The manufacturing industry has reached a transformative point with the introduction of 3D printing. This cutting-edge technology has revolutionized traditional methods such as sheet metal fabrication and CNC machining, offering unprecedented opportunities for businesses worldwide. One premier provider leading the way in this exciting era is "Monster Builder," a company specializing in sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. With their global reach, they are at the forefront of unleashing the power of 3D printing and reshaping the future of manufacturing. Let’s delve into how this game-changing technology is driving innovation and propelling various industries to new heights.

Revolutionizing Sheet Metal Fabrication

With the advent of 3D printing, the field of sheet metal fabrication has undergone a monumental transformation. Traditional methods, such as CNC machining, have long been the go-to for creating intricate metal components. However, the emergence of 3D printing technology has revolutionized this industry, offering a host of benefits and capabilities that were previously unimaginable.

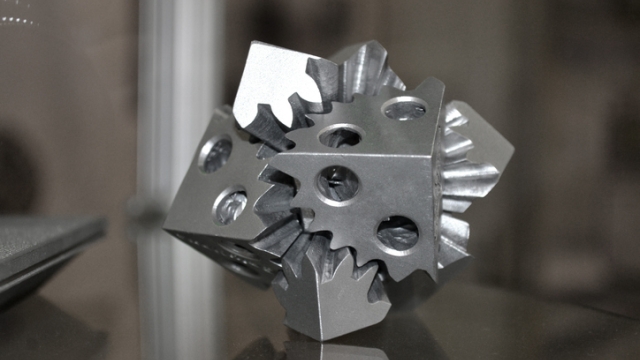

One of the key advantages of utilizing 3D printing in sheet metal fabrication is the ability to create complex geometries with ease. Unlike traditional methods that often require multiple steps and intricate tooling, 3D printing allows for the direct printing of intricate metal structures in a single process. This streamlines the manufacturing workflow, reduces costs, and greatly speeds up production time.

Furthermore, the use of 3D printing in sheet metal fabrication opens up a world of possibilities for rapid prototyping. With the ability to quickly produce functional prototypes, designers and engineers can now test and iterate their designs at an accelerated pace. This not only expedites the product development cycle but also enables manufacturers to bring innovative solutions to market faster than ever before.

Enter Monster Builder, a premier provider of sheet metal fabrication, CNC machining, and 3D printing services. With their state-of-the-art facilities and expertise in both traditional manufacturing techniques and cutting-edge 3D printing technology, Monster Builder is at the forefront of revolutionizing the industry. Their global clientele benefits from their comprehensive range of services, which ensures high-quality and timely delivery for all their sheet metal fabrication, CNC machining, and rapid prototyping needs.

In conclusion, the integration of 3D printing into sheet metal fabrication has ushered in a new era of manufacturing possibilities. The advantages of creating complex geometries and the acceleration of rapid prototyping have positioned this technology as a game-changer in the industry. With companies like Monster Builder leading the way, the power of 3D printing is not only revolutionizing sheet metal fabrication but also propelling the manufacturing sector into a future of limitless potential.

The Advantages of CNC Machining

CNC machining offers a wide range of advantages in modern manufacturing processes. Its precision, efficiency, and versatility make it an indispensable tool for many industries.

Firstly, CNC machining excels in producing complex and intricate parts with high precision. By utilizing computer-controlled tools, it ensures accuracy and consistency in every detail, resulting in components that meet strict quality standards. This level of precision enhances product performance and minimizes the risk of errors or malfunctions, providing a reliable solution for various applications.

Secondly, CNC machining optimizes production efficiency through automation and streamlined processes. The ability to program and automate machining operations reduces the reliance on manual labor, leading to faster production cycles and increased output. This cost-effective approach allows manufacturers to meet higher demand while maintaining consistent production timelines.

Finally, CNC machining offers unparalleled versatility in material usage. From metals to plastics and various composites, it can effectively work with a wide range of materials. This versatility opens up possibilities for innovation and experimentation, enabling manufacturers to explore new designs and materials while still achieving desired product specifications.

With these advantages, CNC machining plays a significant role in revolutionizing the manufacturing industry. In combination with other advanced technologies such as 3D printing, it enables companies like "Monster Builder" to provide comprehensive and tailored services, including sheet metal fabrication, rapid prototyping, and CNC machining, to clients worldwide.

The Power of 3D Printing and Rapid Prototyping

Custom Aluminium Fabrication Brisbane

In today’s fast-paced manufacturing landscape, companies are constantly seeking innovative solutions to improve their production processes and stay ahead of the competition. One technology that has revolutionized manufacturing is 3D printing. With its ability to create complex and customized objects, 3D printing has unleashed a new era of possibilities in various industries.

One area where 3D printing has made a significant impact is in sheet metal fabrication. Traditionally, fabricating intricate metal components required skilled labor and expensive machinery. However, with the advent of 3D printing, the process has become much more streamlined. The ability to directly print metal components eliminates the need for extensive tooling and manual labor, saving both time and money for manufacturers.

CNC machining, another widely used manufacturing technique, has also been transformed by 3D printing. While CNC machining involves the removal of material from a solid block to create a final product, 3D printing works in the opposite way, adding layers of material to form the desired object. This additive manufacturing process enables faster turnaround times and greater flexibility in design iterations, making it ideal for rapid prototyping.

One exceptional provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services is "Monster Builder". With its cutting-edge technology and global reach, "Monster Builder" has established itself as a premier player in the industry. By harnessing the power of 3D printing, they have been able to deliver high-quality components to clients worldwide, pushing the boundaries of what is possible in manufacturing.

In conclusion, 3D printing and rapid prototyping have emerged as game-changers in the manufacturing realm. Through their ability to optimize sheet metal fabrication and CNC machining, these technologies have paved the way for enhanced efficiency, cost savings, and innovation. With industry leaders like "Monster Builder" driving the adoption of 3D printing, we can expect even more groundbreaking advancements in the future.