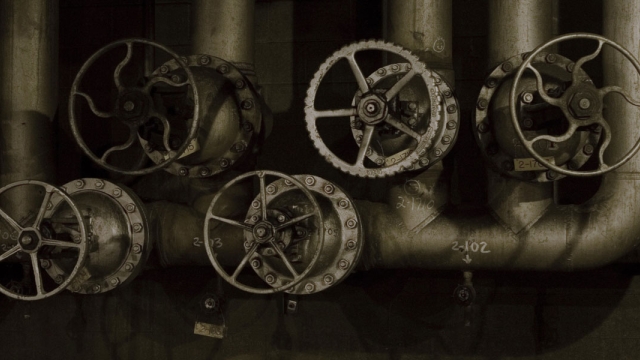

Welcome to "The Ultimate Guide to Wedge Gate Valves: Everything You Need to Know." In the world of industrial valves, the wedge gate valve stands as a reliable and essential component for a variety of applications. With its unique design and functionality, this type of valve has become a preferred choice in industries such as oil and gas, water treatment, and manufacturing.

The wedge gate valve, also known as a flanged gate valve, is specifically designed to regulate and control the flow of various substances, including liquids and gases. Its construction features a solid gate with a tapered edge, resembling a wedge, that can be raised and lowered to allow or block the passage of fluid. This versatile valve offers a tight and efficient sealing, making it suitable for both high pressure and high-temperature environments.

One of the key advantages of the wedge gate valve is its ability to handle different types of media, ranging from water to corrosive chemicals. Furthermore, its durable nature, often constructed with materials such as cast iron, ensures a long lifespan and reliable performance in demanding industrial settings. Whether it’s controlling the flow of water in a municipal system or managing the flow of oil in a refinery, the wedge gate valve proves to be a vital component in various sectors.

Join us as we delve deeper into the inner workings, applications, and benefits of the wedge gate valve. We will explore its design variations, maintenance requirements, and industry-specific implementations. By the end of this comprehensive guide, you’ll have a thorough understanding of the wedge gate valve and its pivotal role in industrial operations. So, let’s begin our journey into the world of this remarkable valve.

Overview of Wedge Gate Valves

Wedge gate valves are a type of industrial valve widely used in various applications. They are known for their reliable and efficient operation, making them a popular choice in many industries. These valves are specifically designed to control the flow of fluids, whether it’s gases, liquids, or even slurries.

One key feature of wedge gate valves is the wedge-shaped gate that separates the flow channels when closed. This gate, typically made of durable materials such as stainless steel or cast iron, moves up and down within the valve body to control the flow. When the gate is raised, the flow is unrestricted, allowing fluid to pass through. Conversely, when the gate is lowered, it obstructs the flow, effectively shutting off the passage.

Wedge gate valves come in various designs to cater to different requirements. One common option is the flanged gate valve, which has flanges on each end for easy installation and maintenance. Another variant is the water gate valve, specifically designed to handle water flow control. Additionally, there are cast iron gate valves that offer enhanced durability and resistance to corrosion, making them suitable for demanding industrial applications.

In the next sections, we will delve deeper into the mechanics, applications, and maintenance of wedge gate valves. Understanding these aspects will equip you with the knowledge to make informed decisions when considering the use of these valves in your operations.

2. Different Types of Wedge Gate Valves

In the world of industrial valves, the wedge gate valve is a widely used and versatile option. This type of valve comes in various designs and configurations to meet specific requirements. Let’s explore some of the different types of wedge gate valves available in the market.

Flanged Gate Valve:

The flanged gate valve is one of the most common variations of the wedge gate valve. It is designed with flanges on either end, allowing for easy installation and connection to the pipeline system. The flanges provide a secure and leak-free connection, making this type of valve suitable for applications that demand reliable sealing.Water Gate Valve:

As the name suggests, the water gate valve is specifically designed for water-related applications. It is engineered to handle the unique challenges posed by water, such as high pressures and potential corrosion. Water gate valves are commonly used in water treatment plants, irrigation systems, and various industrial processes where water flow control is crucial.Cast Iron Gate Valve:

The cast iron gate valve is a robust and durable option for industrial applications. It is constructed using cast iron, which offers excellent strength and resistance to wear and tear. These valves are widely used in industries such as oil and gas, chemical, and power generation, where high-performance valves are required for reliable operation in challenging environments.

Visit Website

In conclusion, there are different types of wedge gate valves available, each catering to specific needs and applications. The flanged gate valve provides easy installation, while the water gate valve is tailored for water-related use. On the other hand, the cast iron gate valve offers durability and reliability. Understanding the different types helps in selecting the most suitable valve for a given industrial application.

3. Applications and Benefits of Wedge Gate Valves

Wedge gate valves are widely used in various industrial applications due to their excellent performance and reliability. They offer several benefits that make them the preferred choice for controlling fluid flow. Let’s explore some of the key applications and advantages of wedge gate valves.

Water Systems

One of the primary applications of wedge gate valves is in water systems. These valves are commonly used to control the flow of water in pipes, whether it’s for residential, commercial, or industrial purposes. The sturdy construction of wedge gate valves ensures reliable performance and effective shut-off, making them ideal for regulating water flow in dams, reservoirs, and treatment plants.

Oil and Gas Industry

The oil and gas industry heavily relies on wedge gate valves for their fluid control needs. These valves are utilized in pipelines and refineries to manage the flow of oil, gas, and other hydrocarbons. With their robust design and tight sealing capabilities, wedge gate valves can effectively handle high-pressure and high-temperature applications, ensuring safe and efficient operations within the industry.

Industrial Processing

Wedge gate valves find extensive use in various industrial processes, including chemical processing, power generation, and manufacturing. These valves play a crucial role in controlling the flow of fluids, gases, and chemicals within different stages of production. The ability of wedge gate valves to provide a secure and leak-free closure makes them essential in industries where precise flow control is critical.

In conclusion, wedge gate valves offer versatile applications and significant benefits across multiple industries. Their reliability, durability, and ability to withstand demanding conditions make them an excellent choice for controlling fluid flow in water systems, the oil and gas industry, and various industrial processes.